Article written by Mayuri Dahibhate, E Tech Group MES Engineer

GE’s Proficy Plant Application software is some of the most robust automation control software out there, with a modular MES design that improves efficiency, documentation, quality, and management throughout a manufacturing facility. The Production Management module in Proficy is responsible for the entire plant’s production operations, including streamlining and managing the flow of products between equipment, and it facilitates schedule changes to reduce excess inventory or to avoid shortage of raw materials. The production module is integrated with the ERP to manage production schedule as well as tracking of materials post-production.

The production management module provides a way to execute scheduled process orders and track production against scheduled completion times with adjustments to optimize efficiencies. This GE automated systems software provides full traceability of individual products through every step of the manufacturing process which allows for genealogy that can be audited and tracked for quality issues. The Proficy Production Management module provides a roadmap of the product flow through the entire lifecycle of the production.

Streamline Workflow for Greater Efficiency & Sustainability

Some of the major advantages of adapting to the Proficy Production module are:

- Improve operational efficiency by gaining knowledge and control over real-time production operations

- Reduce costs of inventory management

- Control the flow of product between equipment

- Manage and report on real time inventories in process

- Integrate quality and production tracking to improve the accuracy of schedule execution

- Generate more revenue by meeting customer demands and government regulations through product genealogy reports

- Tracks products and materials through their entire production lifecycle

- Limit the scope of recalls and quarantines

- Provide faster response to customer issues

- Improved quality assurance due to genealogy tracking

- Elimination of inferior quality raw materials

- Product genealogy is a key component of the Production module. Genealogy allows you to trace a product throughout every step of the manufacturing process and identify exactly what materials and quality characteristics it contains. This allows you to control the flow of product between equipment and manage in-process inventories in real time, enabling you to close the gap between orders and production.

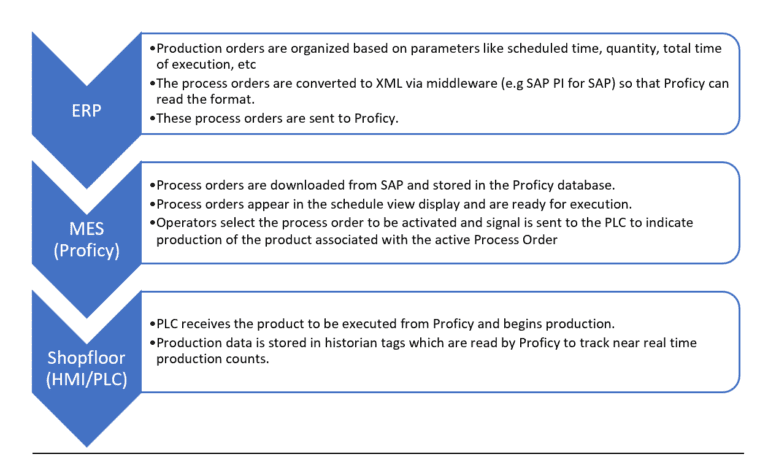

Production Execution Flow (From ERP to Shopfloor):

Process Orders:

- Customer orders are grouped by product and assigned to run on specific production equipment. These are termed as Process Orders.

- ERP is responsible for providing a production schedule in the form of process orders which are downloaded from ERP to Proficy. After they are downloaded to Proficy, they appear in the Schedule View display based on the time of execution.

- Production Plan contains individual Process Orders that are used to determine and track the product, the amount of product, and the equipment to be used to produce these products.

Real-time Interactive Schedule View:

The Proficy Production module uses the “Schedule View” display which provides a real-time interactive view of the process order status and the entire planned schedule.

The schedule view display has following key objectives:

- To automate Production Schedules that are maintained in SAP and often only passed down to the factory floor by means of a daily paper report or spread sheet.

- Provide a single display that shows production schedule and production against the active Process Order which will help the planner as well as Managers.

- Provide operators with a view of actual versus planned production quantities on a near real-time basis

- Provide easy brand changeover functionality.

The schedule view display is primarily used to display and execute the process orders to start production on lines. The current active process order displays tracking information such as actual quantity, planned quantity, planned start time, planned end time, actual start time, etc. The schedule view display also displays near real time production count which helps the operators in planning the activities on the floor.

Production Execution in Proficy Plant Applications 8.x:

With the evolvement of technology and the need for mobility, GE introduced Proficy Operations Hub which switches operations from a machine based thick client to a web based thin client which can be accessed from anywhere and most of the mobile devices which makes it easier for the operators to perform their tasks while on the move on the shop floor. With this advancement, GE also introduced a Proficy Operations Hub based schedule view display.

Here is a video tutorial provided by GE on how to work with process orders using Proficy Operations Hub in Proficy Plant Applications 8.x:

Whichever approach the customer chooses, the production module aims at achieving better product traceability and control over real-time production operations which in turn helps in improving the OEE (overall equipment effectiveness).