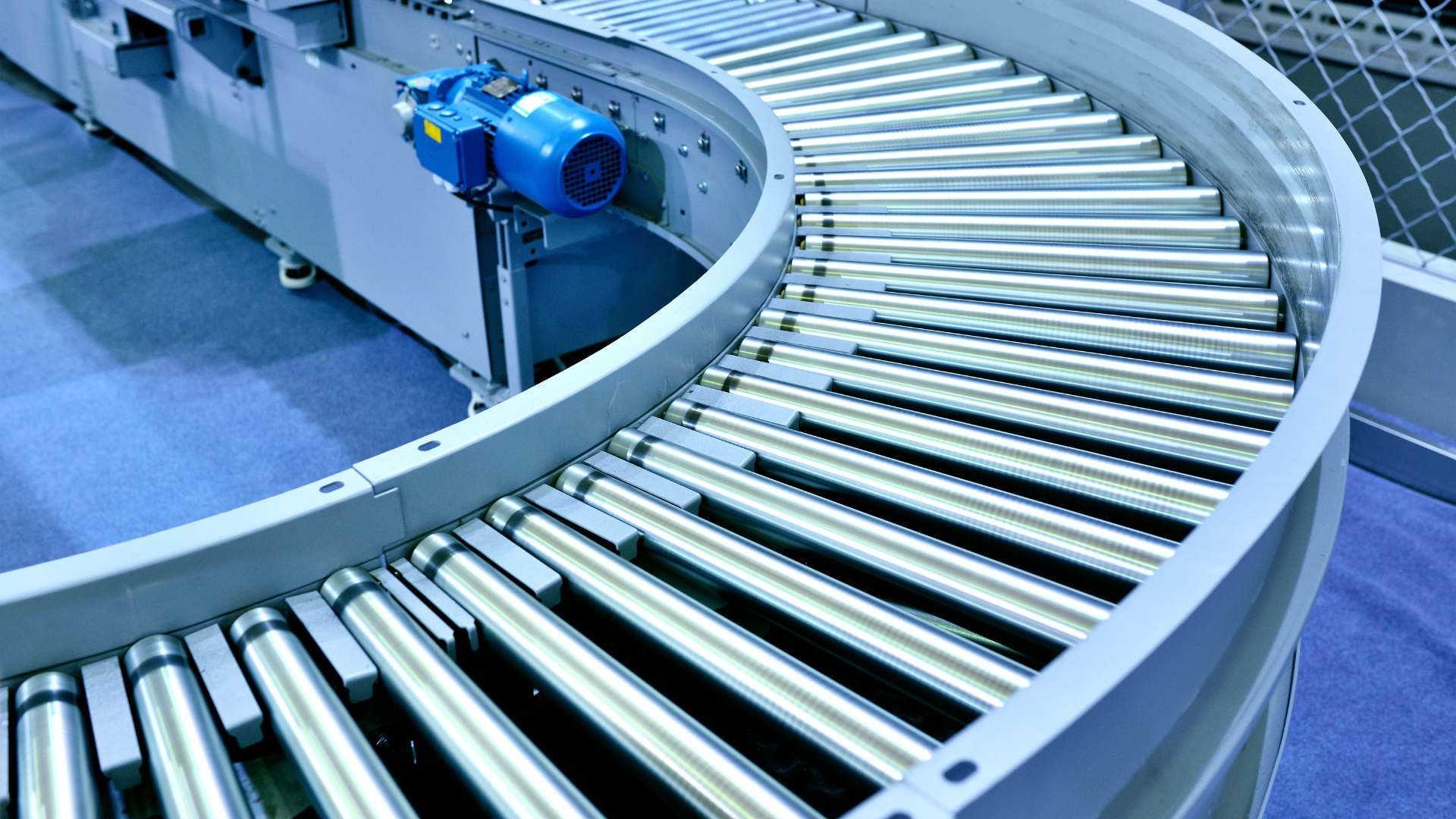

In the article “Planning Tips for Conveying Systems and Lines” from Food Engineering, Trent Meyers, Vice President of Process Industries at E Tech Group, emphasizes the importance of leveraging advanced planning tools in both new and existing facility projects. He notes that many of the same tools used for greenfield facilities can be effectively applied to existing operations. When existing equipment and building models are unavailable, Meyers recommends initiating the process with 3D scanning to accurately define the available space for expansion. This approach allows for the integration of new equipment models with the scanned data, facilitating precise modifications to ensure the desired process functionality. Additionally, he highlights the necessity of conducting comprehensive audits and assessments of the full IT and OT architecture. This information is crucial for system integrators to design and implement the most effective control systems to meet project objectives.Food Engineering

The article also discusses broader considerations in planning conveying systems, such as addressing space constraints, energy consumption, and automation integration. It underscores the value of early collaboration with system integrators and conveyor suppliers, the use of simulation software for modeling proposed changes, and the importance of flexible design to accommodate future modifications.Food Engineering

For a more comprehensive understanding, you click to read the full article below.

Speak with an Expert

Reach out to us here and someone will respond within 24 hours.

"*" indicates required fields