Dealing with Obsolescence Can Become a Bit of a Pickle….

A pickle plant faced obsolete control system hardware but couldn’t afford downtime. E Tech Group’s automation engineers were able to upgrade their decades’ old obsolete system to a current high-speed system in 2 days with minimal downtime.

The Project: A Massive Control Systems Upgrade with No Downtime

E Tech Group engineers were contracted to update and replace obsolete hardware in a pickle plant. This project was time sensitive in two ways: the upgrade is being performed to mitigate impending risk of equipment failure, and the new building automation system must be implemented without halting production.

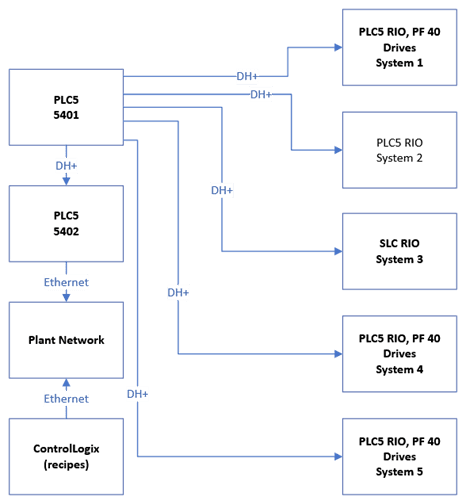

We knew that if the one centralized PLC5 that controlled five systems responsible for 50+% of pickle production failed, they would have to shut the entire plant down to identify and fix the issue, losing valuable time and revenue during peak production periods.

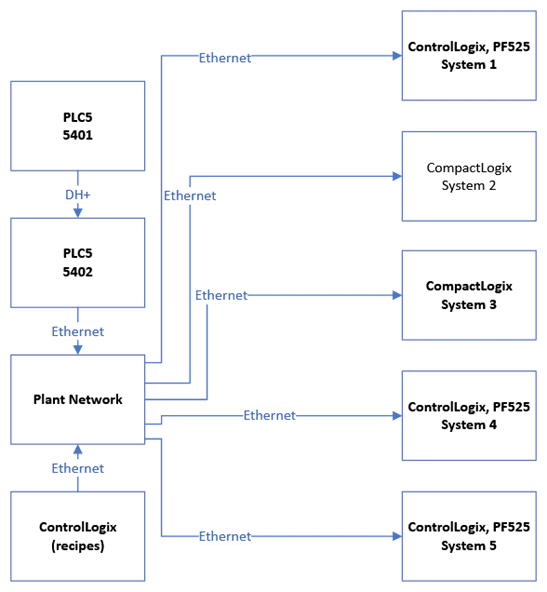

Our automation team knew that in order to upgrade and separate the equipment, the five systems controlled by the central PLC would need to be migrated to either ControlLogix or CompactLogix and all communication transitioned to ethernet.

The Challenges: Time Constraints & High Stakes

Because there were a number of hurdles to take into consideration when beginning this automation system upgrade, it took careful planning to ensure this project could be completed without disrupting production or extending the deadline. First and foremost, we had to untangle and map out the three decades of piecemeal, undocumented control upgrades that were currently keeping the facility operational.

We also had to keep in mind that this facility uses only fresh produce, and at certain times ran at close to 110% production capacity. This meant systems upgrades had to be completed over the weekend and often tested early Monday before they began production, requiring our team to pivot quickly and mitigate any potential hiccups that might occur.

Lastly, the plant itself was located in Michigan, and some of the panels in need of upgrade were outside. If operations were shut down in winter, it could potentially damage the pumps responsible for moving hundreds of gallons of water and pickles from frigid conditions into the plant. We had a small window between cold conditions and production ramp-up to execute, test and ensure operation of the modernized systems.

At this point, clear communication and setting realistic expectations with the client was now critical and of the utmost importance. While we could tailor a solution to their control systems integration that didn’t hurt their bottom line, it would take careful coordination and cooperation to pull it off with minimal disruption to production.

The Solution: Taking Things Apart to Put Them Back Together

Our relationship and open communication with the onsite operations team was invaluable, as it made it much easier to directly identify those five systems in need of audit, and to document the existing setup. This would allow our team to lay out the best solution for such an involved automation and integration install required over a very truncated timetable.

APPLIED SOLUTION:

System 1:

The decision was made to tackle the conversion of the largest system first. It consisted of a 17-slot PLC5 rack and 12 hardwired drives, with a mix of 120V digital inputs/outputs and analog inputs. All of this was converted to ControlLogix and PowerFlex 525s over an ethernet connection. NAT modules were then used to connect the PLCs to the network. This would allow the new ethernet control system to remain isolated while still enabling the controller to communicate with the network.

While the hardware installation was simple, programming proved to be a bit more challenging. Since the original PLC5 had to stay in place, code for the newly-independent system had to be disabled in the PLC5 once the new controller came online. Numerous messages between the old and new PLCs had to be mapped and tested, including some with other controllers. All the IO was then remapped and as much of the process functionality as possible was tested and confirmed operational.

Systems 2 & 3:

While systems 2 and 3 were smaller, they were no less complicated. Due to spatial constraints, CompactLogix controllers were used instead of ControlLogix. Communication with the original PLC5 still had to be set up and tested, while messaging between the PLC5 and each of the new controllers had to be configured.

Control was then disabled in the original PLC so the new ones could be tested. We were then able to remove the disabled logic in the original PLC5 for system 1 as it had been running for several weeks with no issue and established confidence in the new controller.

Systems 4 & 5:

The conversion for systems 4 and 5 were similar to system 1. PLC5 IO racks utilized hard-wired drives, and both were converted to ControlLogix and PowerFlex 525 drives over ethernet. As in system 1, NAT modules were used to keep the systems on the plant network but remain isolated. The same cutover approach was repeated as with the first three systems where logic was disabled in the original PLC as systems 4 and 5 came online.

Messaging between the original PLC5 and the new controllers was configured, along with communication to several other controllers. Disabled logic in the original controller for systems 2 and 3 was removed at this point. We were then able to remotely remove disabled logic for systems 4 and 5 when it was determined safe to do so.

The Results: This Control System Integration was Kind of a Big DILL

As with any large installation to be completed quickly, the need for troubleshooting issues can increase. Because we upgraded a decades-old obsolete system to a current high-speed system over a weekend, there was more testing and calibrating necessary than if it were a simpler, incremental upgrade done over time.

Learning the client wanted to walk in Monday morning and resume production at 100%, our team had to manage those expectations by communicating the need to ensure functionality at all stages of production, and that they would need to begin at 50% and increase gradually to 100%. This would allow for an easier shut down to solve any potential bugs or hiccups that may arise before reaching full production.

Our team’s clear communication and ability to manage the client’s expectations, coupled with the expert work of our engineers, has opened the door to a multi-year project with the potential for future work. Except now we know that next time, they won’t be in nearly as much of a pickle.

Challenge

The pump-over method plays an important role in modern wine extraction and can impact the wine’s flavor, intensity, and color. For a Californian winery, their red fermenter tanks used manual pump-over technology, but it was experiencing inconsistent timing as well as limited electrical capacity to run all pumps simultaneously. For instance, each Motor Control Center (MCC) could only run 50-70% of the pumps at a time. The winery needed to upgrade to an automated pump-over system to improve monitoring and control performance, reduce maintenance costs, and support their production needs. E Tech Group was engaged upgrade their existing tank controls effectively and efficiently given their expertise with similar projects in the wine industry.

Solution

The first challenge to address was the customer’s limited electrical capacity to run their pumps simultaneously. E Tech Group created a first in, first out (FIFO) scheduling algorithm for each MCC which would allow the pumps to run in the order that they were scheduled. The FIFO scheduling structure simplified the pump-over process, queuing pumps to run based on priority with the customer’s electrical capacity in mind.

With the algorithm established, the E Tech Group team pivoted to tackle the next area of support. The customer needed an automated pump-over system that was user-friendly, powerful, and modular. The team leveraged the customer’s existing ControlLogix PLC and Ignition SCADA platform by Inductive Automation to build robust code that could be swiftly tested and deployed. For example, the project team utilized the add-on instruction (AOI) to maximize code reusability and simplify code development in the ControlLogix PLC programing. Ignition’s user defined types (UDTs) were also utilized as a powerful tool for dynamic system modeling, and field devices, such as flowmeters and temperature and pressure sensors, were IO-Link enabled to provide diagnostics and data more effectively.

Results

The customer was equipped with a fully automated pump-over system for their red fermenter tanks by their upcoming grape harvest. E Tech Group’s subject matter experts in wine processes and the Ignition platform fully automated the customer’s existing pump-over technology, improving its efficiency, reliability, and ability to scale with the growth of the company.

Challenge

From decreased productivity to system downtime, legacy equipment can pose many challenges to operational efficiency. This was the case for a leading consumer packaged goods company who was relying on PLC-5 hardware to control most of their facility. The plant recently experienced a major disruption during peak production because of a network switch failure, and it was later discovered that the disruption could have been minimized if the facility had been separated into multiple virtual local area networks (VLANs). To support the creation of VLANs, the customer’s existing PLC-5 control system would need to be upgraded to the ControlLogix system which could handle multiple independent Ethernet connections. E Tech Group was called to support the project given their previous assistance with consolidating the company’s DH+ and ControlNet network communications in support of their industrial automation applications.

Solution

E Tech Group performed a comprehensive investigation to identify all PLC types and determine each PLC’s connection to other systems. After completing their analysis, E Tech Group presented which PLCs were deemed the most critical to upgrade and designed a VLAN separation plan to reduce the likelihood of connection loss given the vast amount of device communications. The customer’s personnel were initially surprised by the number of PLCs that needed to be upgraded to fulfill the VLAN implementation, which was about 21 PLCs. For the best implementation process, it was determined to perform the PLC upgrades in three phases with the first phase switching out the most critical PLCs.

Six PLC-5s needed to be upgraded in the first phase. E Tech Group considered several factors to include local and other server racks, a labor-saving conversion kit, the maintenance of other communications protocols, and ways to thoroughly test the success of the conversion. The customer also requested the migration and testing be completed within 72 hours. With these considerations in mind, E Tech Group worked closely with the customer to determine the best conversion process within the short timeframe. This included the use of only replacing local racks, using DH+/RIO and ControlNet communication modules to support existing networks, complete I/O list development, and spot testing plans. A PLC-5 to ControlLogix conversion tool was utilized to migrate logic from the old hardware to the new hardware, and all drivers were updated in the Wonderware system to allow for proper communication to the new PLCs. DH+/RIO ControlLogix cards were also used to connect into existing DH+ networks and allow ControlLogix PLCs to talk to existing PLC-5 Remote I/O racks.

Results

The project was commissioned on a Friday of a holiday weekend and was completed that Monday. Committed to the success of the project, E Tech Group had two teams supporting the project throughout the entire weekend in 12-hour shifts. In a few short days, E Tech Group was able to have the six PLCs successfully migrated by the customer’s requested timeframe and resolved numerous pre-existing issues within the logic by the time the PLC’s remote monitoring was completed. Using the knowledge gained during the first phase, the next two phases were completed with much smaller teams and the customer had the ability to improve their operational efficiency with a control system platform.

Challenge

“If you fail to plan, you are planning to fail”. This quote by Benjamin Franklin emphasizes the importance of site surveys for industrial environments. With time, money, and resources on the line, site surveys act as a crucial first step to plan for maintenance, spare parts, upgrades, and mitigate the risk of unplanned downtime. This critical information was needed by a leading American food distributor to better understand the health of their plant’s automation infrastructure. E Tech Group was engaged to thoroughly assess their automation hardware and operational technology (OT) networks and provide a comprehensive site assessment report. This report would clearly identify risks and opportunities as well as crucial steps to upgrade and strengthen their automation infrastructure.

Solution

The customer’s plant had three buildings which included over 500 control panels. E Tech Group analyzed numerous factors and data points to determine areas of risk and opportunity across their plant. This included the lifecycle of parts that are currently being used on the production floor as well as the equipment’s life cycle positioning ranging from active to end of life. E Tech Group’s certified professionals also evaluated existing processor types and quantities across the plant and documented the customer’s OT network infrastructure.

The data collected from the site assessment was then organized and analyzed to serve as a roadmap for facility improvements. E Tech Group formulated a comprehensive, well-structured report for the customer’s management, engineering, and maintenance teams which outlined upgrade recommendations and a clear timeline to implement these upgrades based on the priority level.

Results

E Tech Group worked closely with a plant electrician to complete an on-site assessment of all control panels and OT networks in less than eight weeks. The data from the site assessment was used to provide a comprehensive report outlining automation infrastructure by area, OT network architecture, obsolescence, and recommended paths forward to modernize. The site assessment resulted in a proactive plan to reduce the customer’s likelihood of future controls hardware failures and provided a clear roadmap to strengthen their automation infrastructure.