Discover the Benefits of AI in Process Automation Solutions

As AI becomes accessible, manufacturers benefit from AI implementation in process automation and controls. Learn how AI adds value to operations in any sector.

We’re your source for automation news. Keep up with the latest industry updates and E Tech employee spotlights, as well as tips and guidance from our manufacturing experts.

As AI becomes accessible, manufacturers benefit from AI implementation in process automation and controls. Learn how AI adds value to operations in any sector.

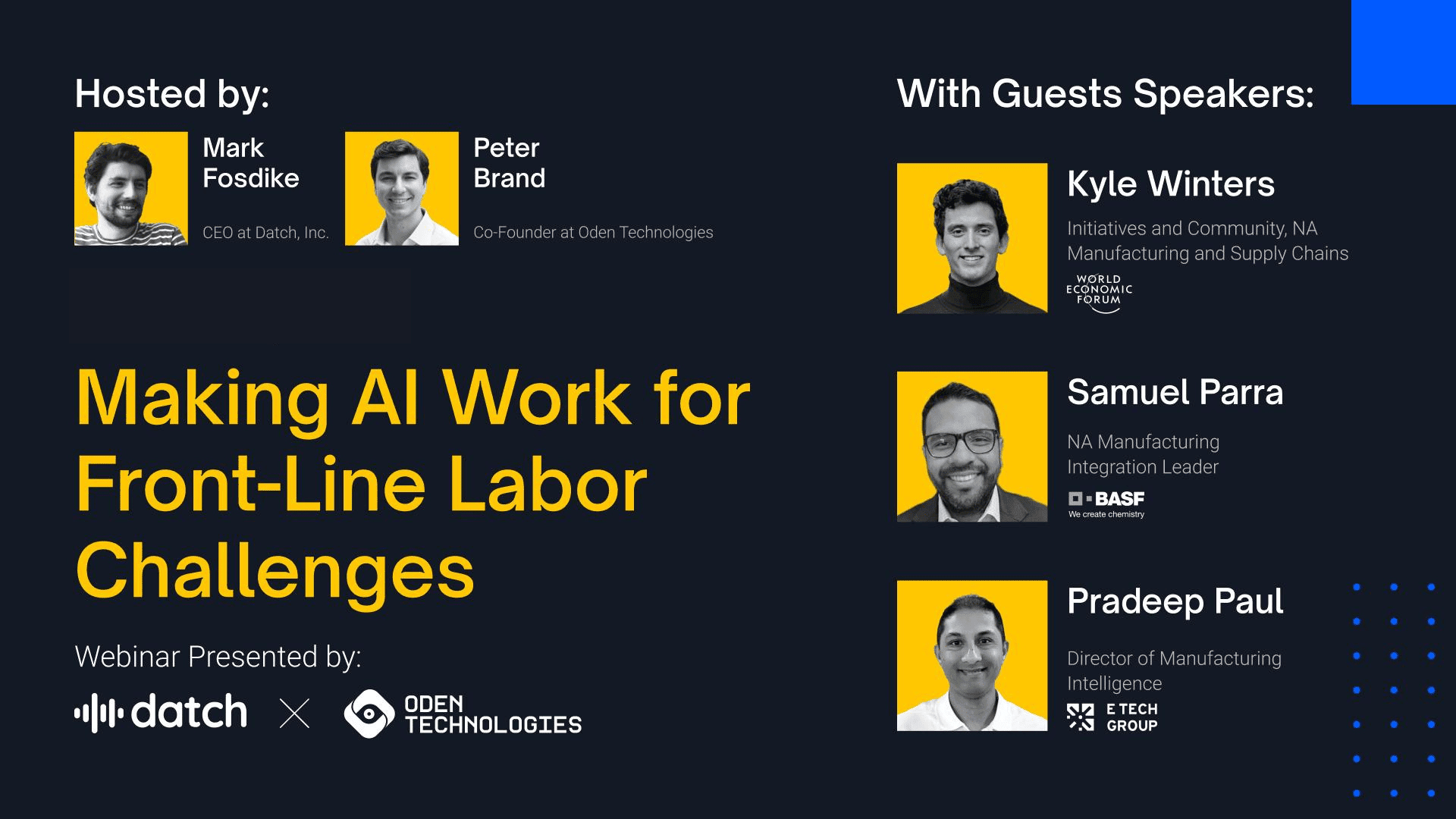

Join us for the Making AI Work for Front-Line Labor Challenges webinar with Datch, Oden, and E Tech Group! We’ll explore how AI can boost front-line productivity in manufacturing—a crucial topic as average front-line tenure has dropped from 20 years to just 3, creating a significant skills gap.

On August 20, 2024, E Tech Group’s Cybersecurity Specialist Matt Smith sat down alongside Vice President of Business Development Laurie Cavanaugh for a candid but in-depth discussion addressing cybersecurity for the OT network. The webinar, entitled “Fact or Fiction: Debunking Industrial Network Security Myths,

On August 20, 2024, E Tech Group’s Cybersecurity Specialist Matt Smith sat down alongside Vice President of Business Development Laurie Cavanaugh for a candid but in-depth discussion addressing cybersecurity for the OT network. The webinar, entitled “Fact or Fiction: Debunking Industrial Network Security Myths,

E Tech Group © 2025 | All Rights Reserved.