What is a Controls and Automation FEED Study?

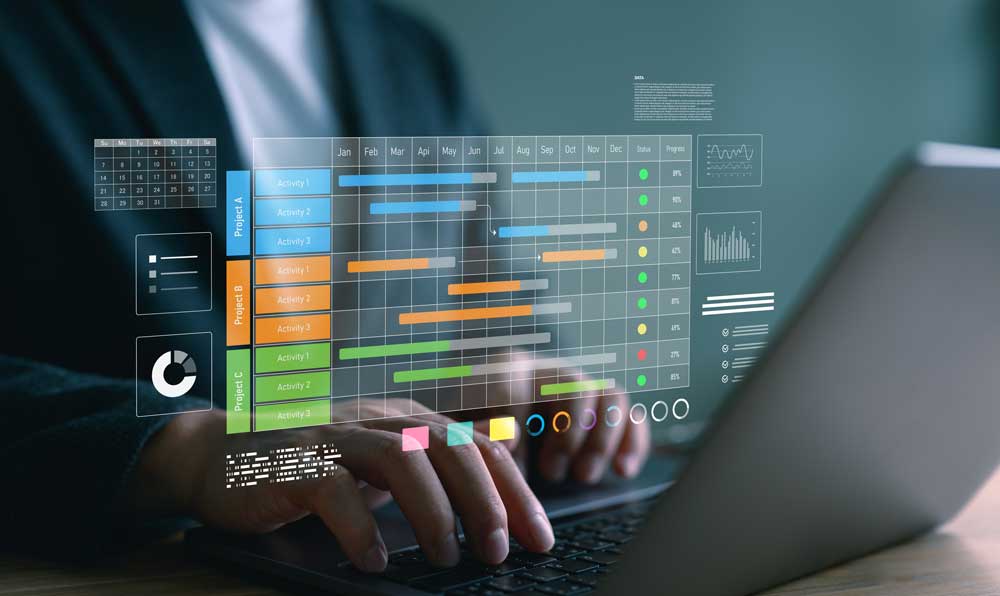

A front-end engineering design (FEED) study is the critical early planning phase in the development lifecycle for industrial manufacturing and infrastructure projects. It involves conceptualizing and planning the technical, economic, and scheduling aspects of a large project to make informed investment decisions prior to implementation and construction.

A controls and automation FEED study delivers detailed planning documentation for the project, a roadmap that guides the next steps for the project’s execution, including procurement, detailed engineering and implementation plans.

E Tech Group’s controls and automation FEED studies are specifically designed to address the unique challenges of designing advanced automation systems. Critical design decisions are made that ensure reliability, efficiency, compliance, and scalability to best meet the diverse needs of stakeholders.

Some design decisions include:

- Advanced control hardware

- Software platforms

- Process flow

- Communication networks

- Equipment sizing

- Layout configuration

Each decision has a lasting impact on the final system’s performance and operational reliability, as well as the project’s schedule and overall budget.

By conducting a well-structured FEED study, E Tech Group helps clients make the best decisions for their own unique needs, optimizing resources, avoiding costly mistakes, and keeping the project on schedule.

Why Choose an E Tech Group FEED Study?

When Should You Consider a FEED Study?