The Project: Help a Client Circumvent Labor Shortages with Robotics Automation

A food manufacturing facility located in Greenville, SC was experiencing bouts of labor shortages, extremely high turnover and retention, workplace injuries, and impacted output that could all be traced back to the packaging and palletization area in their facility. This physically-demanding manual process was starting to threaten the company’s operations and employee safety.

Before reaching out to E Tech Group, this palletizing process was one-hundred percent manual. There were fourteen full-time employees that were able to pack and palletize enough product to produce 1.5-2 truckloads for shipment per day. Unfortunately, there were a number of contributing factors that were severely limiting the desired output.

The Challenges: Complications Inside & Outside the Facility

Because this facility was located in a warmer climate, temperatures could reach over one-hundred degrees in the hotter months. This, coupled with the facility being dedicated to food and beverage production, the workers on the floor couldn’t have beverages of any kind outside of their allocated breaks throughout the day. This could make it difficult to remain hydrated and contribute to work-related incidents.

There were often too many employees attempting to navigate narrow walkways in increasingly-crowded spaces, adding to the already hot temperatures and exacerbating the possibility of potential injury. In some cases, not just a possibility, but numerous violations and lax regulations allowed sub-par pallets to be handled and used in their palletization and shipping process, leading to 40% of the recordable OSHA incidents coming solely from this area.

On top of all this, it was brought to our attention that the majority of individuals working in this area were contracted by a temp agency and would often only last a week, and on certain occasions, just until lunch. It was clear to our team that all of the aforementioned conditional issues were heavily influencing the incredibly high turnover this facility was experiencing, even before COVID, and continued to only get higher during.

The environmental and physical working conditions were enough to truly drive the need for automation in an area that really wasn’t optimized for human labor. Implementing robotic processes and an integrated control system would allow personnel to deal with palletizing from the safety of an HMI instead of dealing with a taxing, risky and inconsistent physical process.

The Process: Environmental Factors & Available Capital Push for a Creative Solution

Understanding that this facility had a number of issues impacting retention and consistency in their workforce, and the ultimate goal being to automate those positions not suited for human labor, the applied solution would need to be designed taking into consideration the limited resources available to monitor and maintain this installation. This would allow the client to reallocate and retrain existing skilled labor to fill new positions without the need to rely on temp agencies for additional workers.

Second to available manpower, the limited physical space continued to plague the design team. Knowing this already overcrowded space was susceptible to frequent workplace injuries, they would be forced to think outside of the box when positioning the equipment for an automation solution that would be erected in an area not conducive to added equipment.

Not only was accommodating the lack of real estate a large undertaking, but addressing the dated infrastructure quickly moved to the top of the list. Realizing that any installed solution would require new and dedicated power to ensure reliability, it added a slightly complex layer to an already intricate project.

The last and perhaps most critical challenge to address and overcome was stakeholder approval. Understanding this facility had been facing an output deficit impacting their profitability, getting them to spend more money was no easy task. Our team provided several iterations of the proposed solution, but it proved to be an exercise in futility.

The Solution: Strategic Segmentation Provides a Budget-Friendly Design

After all proposed solutions were rejected by the decision makers due to budgetary constraints, our team decided to position a phased approach. This would allow them to spread the large investment required to help realize their business goals across a number of installations. Satisfied with the first and second phase and proposed cost, the E Tech Group team began to execute!

PHASE 1: Planning

Design a comprehensive automation solution that maximized use of space and minimized need for worker traffic.

PHASE 2: Application

Procure the necessary automated equipment, build the robotics control system, program, install, commission, and train employees on the new system.

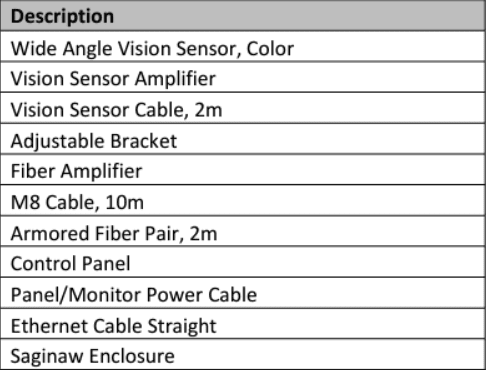

Major Equipment:

- Palletizing cells, safety fence and scanner system

- Pallet conveyor

- Pallet dispenser

- Pallet wrapper

- AGV system with stacked dual conveyor cart

- Case conveyor

- Mezzanine in filler room

- Safety gate for existing mezzanine

Electrical Equipment:

- PLC control panel

- Case conveyor

- 800A bucket for MCC

- 480VAC power distribution panels

- Case conveyor motor disconnects

- Distributed I/O sensors/solenoids/brackets

- Pallet conveyor VFD panel

- Pallet motor disconnects/brackets

- HMI

Once the initial challenge of running dedicated power for this control system installation was complete, these combined and installed components created a fully-automated solution that drops a box from an elevated mezzanine to a fill area below, shakes to level and then moves the full box through a taping station as it heads down a conveyor, where it is then diverted to the correct palletizing area.

A palletizing robot picks and places the sealed box in its designated spot on the pallet, and once full is secured by a pallet wrapper. When the pallet is ready to move to the shipping area, an AGV removes the full pallet, then adds more empty pallets to hopper that will repeat this process.

By automating the client’s palletizing processes in this way, E Tech Group helped them remedy the multivariable dilemma that this manual process caused the company – namely, high turnover, an unsafe environment, and the output limitations symptomatic of the first two.

PHASE 3: Future Work

Add automated case erectors on mezzanine to automatically provide empty cases.

The Results: Tangible Results on an Immediate Scale

The benefits this custom automation system provides this client made the challenges we encountered throughout the project worth it. The roboticized pallet system bore several positive results:

Decreased Safety Incidents and Increased Production

Our E Tech Group team took this from a completely manual process to an automated one. This facility redeployed two-thirds of their twelve full-time employees from this area to other areas in need, helping eliminate overcrowding and decrease the number of safety-related incidents. This left only three employees to monitor this new system which almost doubled the production and output rate; from 1.5-2 to 2.5-3 truckloads per day.

Long-Term ROI Considerations

The implementation of a solution designed to automate a once manual process, replacing 12 manual labor positions, has exponential ROI potential. When positioning this solution, it was critical to understand the facility’s challenges and goals. E Tech Group believes the continued completion of the next phases will only compound the ROI considerations first identified when taking on this project.

Reduction in Accidents/Lost Time Accidents

The new automation system anticipated a reduction of as much as 40% of the OSHA recordable incidents that occur in and around pallet handling. This, in turn, improved their safety record, reducing claim impact and insurance premiums, as well as lost time resulting from work-related incidents.

Reduced Administrative Burden for Labor Acquisition

Automating the palletizing process enabled the management team to increase efficiency, as they would no longer be tasked with perpetual recruiting, onboarding, supervision and scheduling of a constantly-changing labor pool. This allowed these departments to be more effective, adding even more return to the facility.

Ability to Accommodate Future Capacity Increases

These phased upgrades will allow for easier future optimization, increasing throughput and allowing the client to stay competitive.

Risk Mitigation/Predictability

Because the human being represents a fairly uncontrollable variable, susceptible to injury, illness or unpredictability, the transition to automation largely eliminates those risks. The client would now be able to more accurately predict and complete throughput benchmarks; ensuring order consistency and packaging quality.

Competitive Advantage/Enterprise Value

While automation provides an increased level of predictability to the business, it also provides the image of a state-of-the-art industry leader to a prospective customer or buyer that is visiting several potential vendors. Setting yourself apart as a company that continues to invest in their business can be invaluable. In all, this complete manual-to-robotics switch helped the client in several ways. While it was challenging to design and implement a cutting-edge system in an outdated and cramped facility, the benefits outweighed the cost immediately, and will continue to offer the client long-term returns. And E Tech Group will be there to support their automation endeavors every step of the way.