When a prominent manufacturer wanted to observe and interact remotely with their production line in real-time, E Tech Group software developers brought their 3D game development expertise to deliver an innovative digital twin of the line. The twin mimics the behavior of its real-life counterpart in real time, visible in a 3D environment via web interface. Following its initial success, E Tech Group engineers broadened the tool’s scope to be fully configurable and controls system agnostic. They have plans to further expand upon the digital twin’s capabilities.

Creative Tools are Born of Full OT Network Connectivity

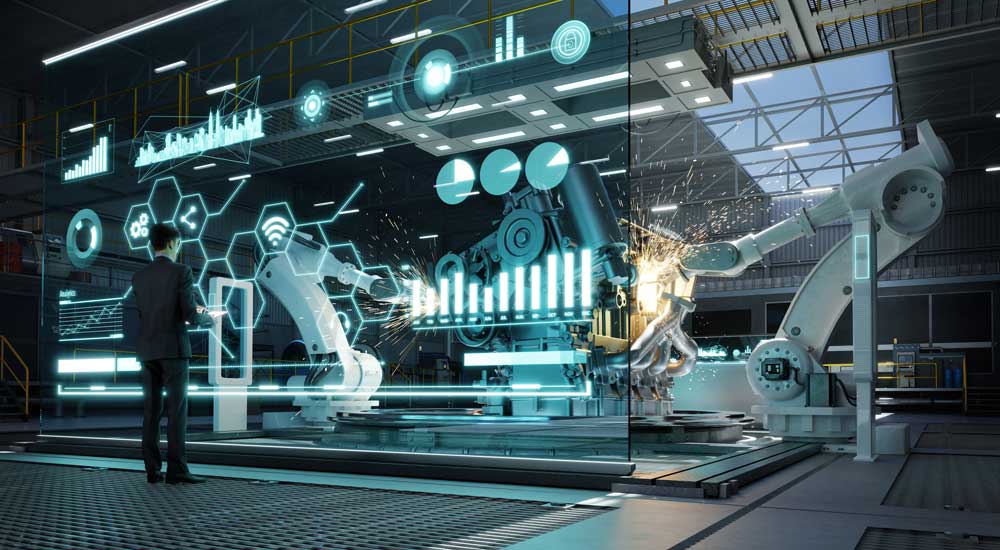

As the manufacturing industry continues to move towards digitalization and Industry 4.0, physical systems and digital technologies are converging, resulting in highly creative tools that facilitate and optimize all parts of the production process. Obtaining full OT network connectivity is foundational to the future of large-scale manufacturing, as it opens the door to a variety of data-driven tools.

One such tool that’s gaining traction for a variety of use-cases are virtual representations of a physical system, popularly called ‘digital twins.’ This article discusses the development of digital twins and reviews some of the creative ways they can be used for monitoring production, troubleshooting and process optimization.

What is a Digital Twin?

A digital twin is a virtual representation of a real-world system. In the context of automation in manufacturing, the ‘twin’ that is created can range in size and scale from a singular piece of equipment, all the way to a full production line, or even multiple production lines.

As a virtual counterpart, a most basic digital twin is set up to visualize the behavior of the physical system it represents in real time – a virtual display. Created by collecting data from sensors and other equipment in live machinery, this telemetry information is then sent to and visually interpreted by a virtual representation of each component of the system in a 3D environment. As a result, the twin’s motion mimics the equipment it represents and does so in real time.

Beyond building a basic visual display of a system, digital twins can be used for more complex applications including:

- Testing control logic without risking damage to the real system

- Applying machine learning algorithms to model the dataset and predict upcoming points of failure

- General troubleshooting

- Optimizing production line layout and flow

- Operator training exercises

Essentially, a digital twin provides a fully-accurate, real-time, scaled model of your facility’s automation system that allows comprehensive remote monitoring and troubleshooting abilities. A subsequent offline copy of a fully-built digital twin can then also allow you to experimentally dissect, analyze and even disrupt the system with zero real-world consequences of physically doing those things.

Equipment Digital Twins are Like a Production Line Video Game

E Tech Group’s digital twin development is being accomplished by leveraging expertise from an entirely different technology sector – video game development. For a digital twin to be most useful, it needs to operate in the same manner as its real-world counterpart, obeying the laws of physics.

Video game developers have been creating tools to mimic the real world for a long time. They’ve built sophisticated physics engines that govern the physical interactions of objects within a system enabling realistic modeling of classical mechanics principles including:

- Kinematics and dynamics

- Force of gravity

- Newton’s three laws of motion

- Force of friction

- Collisions theory – conservation of momentum and impulse-momentum theorem

- Rotational kinematics and dynamics

- Simple harmonic motion

E Tech Group’s digital twin team consists of software engineers with game development experience as well as controls engineers with manufacturing-specific expertise. Together, their combined knowledge allows them to build state-of-the-art virtual tools that begin with the basic digital twin.

Building a Basic Digital Twin in Unity

The E Tech Group digital twin team is using the Unity development environment for this purpose. This tool originated as a cross-platform game development engine to enable development of 3D video games. As a result, Unity includes a highly developed physics engine meeting the criteria described above, as well as graphics rendering and scripting capability.

Each component in the system must be visually represented in the Unity environment. A basic visual display twin is directly connected to telemetry data from its real-world counterpart. A more advanced twin does not require live telemetry data for use. Instead, the system’s behavior is entirely described via Unity’s physics engine.

Components to Include when Building a Digital Twin:

A digital twin is constructed by incorporating all the elements in the real system into the virtual environment. This includes:

- All physical components of the automation system (robots, conveyors, machinery, safety features, general purpose areas). The goal is to accurately represent the layout of the physical system.

- Control systems: Modeling all control and automation logic (PLCs, control panel HMIs, SCADA systems) within the digital twin will ensure it replicates the behavior of the physical control system.

- User interface: If desired, building a friendly user interface will allow effective interaction with the digital twin.

- Virtual sensors: By integrating virtual sensors into the digital twin, it can be used as an innovative means of capturing real-time data for the purposes of monitoring and general analysis, including production optimization.

CAD Models as the Basis of its Virtual Representation

A CAD file can be used as the basis of each component in the digital twin. Unity allows CAD files to be imported directly into a project, although they must first be converted into a supported file format. Unity Pixyz is a plugin tool that accomplishes this task for most proprietary CAD file formats (Solidworks, AutoCAD, CATIA, etc).

Database Data Collection Versus Live Data Feeds

Real-world data from sensors can either be directly connected to the model or alternatively, it can be transferred to a database and then accessed by Unity to drive the models. E Tech Group’s automation software developers have chosen to connect its digital twins to a database. They use InfluxDB for this purpose as it’s designed for handling high volumes of time-stamped data. Likewise, it’s also optimized for querying and visualizing this data as is done by the digital twin 3D model. Database connectivity offers a variety of benefits, including:

- Storage of historical data associated with past performance for later analysis.

- Reduced dependency on real-time connectivity as data integration allows for buffering and storage of data.

Performance Requirements

- Controls system: The real system including PLCs and other equipment must be connected to an OT Network to capture data. Likewise, legacy controls may require upgrading to ensure the processor has sufficient processing power and capability to both run the controls for the real system as well as send data to the database.

- Simulation: Utilizing the physics engine requires large processing power as a tremendous amount of time-sensitive calculations are required to simulate the digital twin with reasonable accuracy.

- The database server receiving data from the equipment needs to be fast and optimized for storing large amounts of time-stamped data. E Tech Group uses InfluxDB for this purpose.

- The visualizing clients can be run via nearly any laptop or device. Multiple client devices can be visualizing the system at the same time.

Why Implement a Digital Twin?

By implementing a digital twin, remote monitoring and troubleshooting become much simpler, as points of failure in the facility’s automation system can easily be identified without any need for someone to physically be on the floor. When a production issue arises, the remote engineer can view the digital twin system from any perspective within the virtual environment. As a result, remote troubleshooting can solve more elaborate issues than otherwise, potentially reducing production downtime and engineer travel time.

System Design, Commissioning, Training and Troubleshooting via Digital Twin

Once a digital twin is fully built and connected to a telemetry data source, a second copy of the twin can be implemented to function offline, not connected to this live data source. Instead, it draws from the physics engine within Unity to determine the motions of the system based on virtual inputs. This opens up some interesting applications:

- Failure Prevention and Analysis: Machine Learning algorithms can be applied to historical Internet of Things (IoT) data to analyze the trends over time and train a model. Initially, this model can help identify and diagnose points of failure. As it continues to learn, the model can be setup to alert engineers before a critical failure occurs, allowing them to take immediate action.

- Software Commissioning: A digital twin can be set up for use based entirely on the physics engine of Unity. While this may not be fully accurate, it can serve as training grounds to exercise, test and debug system software before the real equipment is available. Software can be nearly fully debugged prior to testing it on real equipment, streamlining control system implementation.

- System Design and Optimization: Once again, setting up a digital twin based entirely on the physics engine of Unity provides engineers a virtual environment to optimize the design of a line via the best line layout, type of equipment, production flow, etc.

- Virtual Sensors for Data Collection: Virtual sensors can be added to a digital twin to monitor parameters of interest. This opens a highly creative, low-risk, zero downtime, low-cost means of monitoring various parameters within a real system.

- Training Simulation: Historical data can be used within the digital twin to set up interesting initial conditions. The physics engine can then be used to drive the behavior of the twin in a way that’s realistic with how the physical system would respond. People interacting with the twin can then manipulate certain system inputs or parameters to learn more about the expected behavior and outcome for the real-world system.

Bringing Automation into the Virtual Age

Virtual representations of a physical automation system, popularly called digital twins, are a creative new tool that’s emerging for use as manufacturers move towards full digitalization of their production lines. By upgrading controls systems and connecting all equipment, the digital twin allows any individual to remotely view and monitor their equipment in a fully 3D environment.

Creative applications stemming from the digital twin will continue to emerge offering new ways of designing, commissioning, training, optimizing, and troubleshooting a process. As demand on all industrial and manufacturing sectors continues to increase, an asset like digital twin allows our clients to keep a leg up on the competition by providing the ability to look behind the operational curtain and gain unprecedented insight into the realities and possibilities of automation.

Contact Us

"*" indicates required fields